Pumps, Compressors, Valves

Purpose: With the advent of high quality resin 3D printing, I always thought it would be kind of neat to create a mold and sand cast a part. Fun fact but a lot of components in turbochargers are sand casted; most notably the compressor cover, turbine, and bearing housings. I model the parts below and obtain a CFD solution (no design parameters):

Volute:

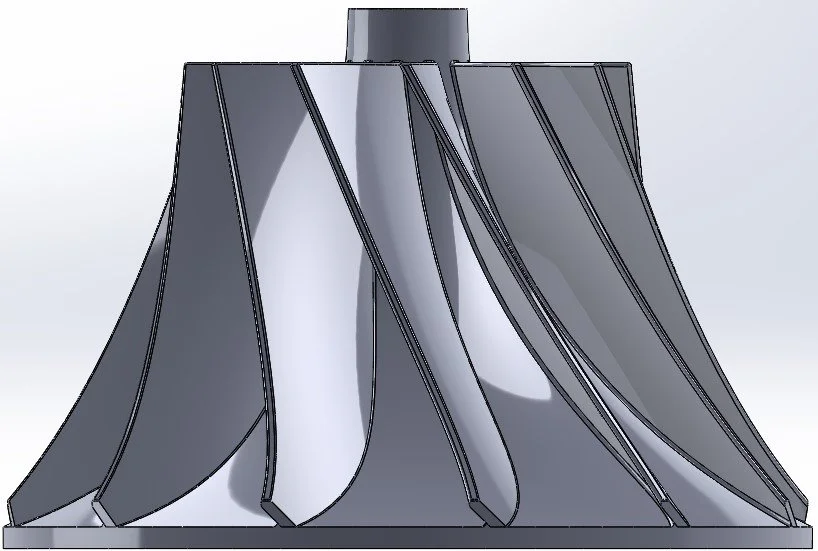

Compressor wheel:

Assembly [Compressor stage]:

Using water as a working fluid. Noticed something was off with the pressure outlet within ~5 minutes. Let it finish running.

Chose the wrong direction for my rotating region. I changed the direction and reran it.

Looks way better. Pressure outlet is starting to make more sense.

Nice to see the cut plot show where the velocity is at a maximum, the pressure is at a minimum. This is verifiable by Bernoulli’s equation whereby pressure is inversely related to velocity.